News

Presentation - Application of Longsys; In-vehicle Storage on Smart Vehicles

2021.06.03

The ecological quality and technical strength of China's smart automobile supply chain have been improving. Car manufacturing has gradually evolved from a closed system to turnkey. Both traditional car enterprises and new emerging forces in car manufacturing are engaging in transformation and upgrading in anticipation of the future role the smart car market will play.

Thanks to intelligence, the very concept of what an "automobile" can be are evolving - what was once simply a means of transportation is changing into a mobile terminal. Along with this evolution comes new market opportunities for storage device manufacturers. At present, storage devices are being used in infotainment systems, vehicle monitoring systems, vehicle personal data, power systems, and the Advanced Driving Assistance System (ADAS). The demand for storage quality and capacity is bound to increase with the further development of automation in the future.

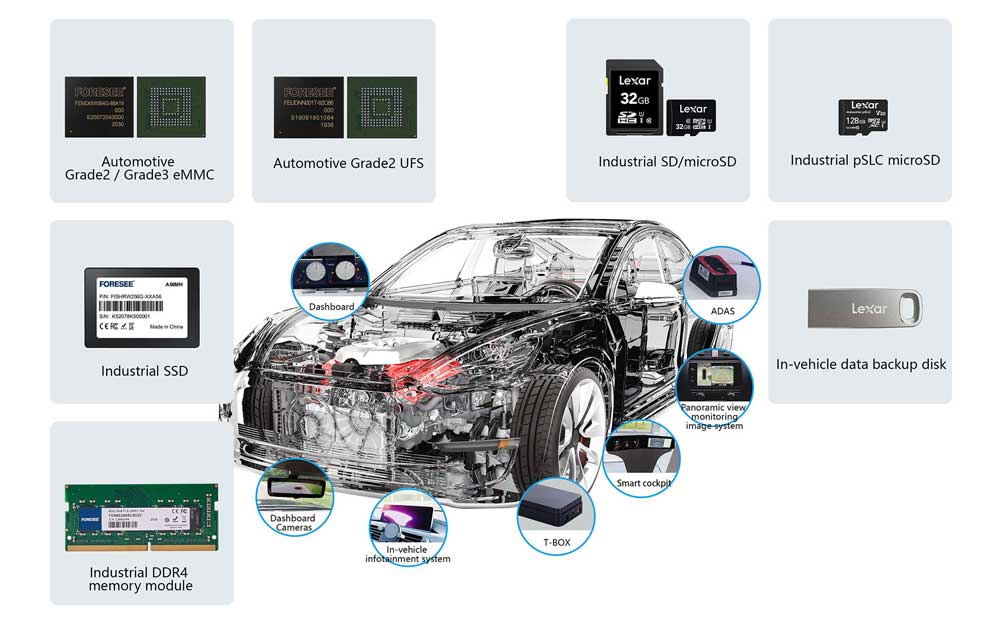

In recent years, Longsys has been vigorously expanding its business in the vehicle storage market. Its in-vehicle storage products delve deep into every aspect of the vehicle, as they are applied in various fields ranging from both factory-installed and aftermarket-installed automobile and high-speed railway products to public transportation. Now, Longsys is cutting a figure in the vehicle storage market with its automotive storage eMMC, UFS, industrial SSD, DDR4 memory module and memory cards, in-vehicle data backup disks, and even customized technical products.

Longsys is up to the challenges presented by in-vehicle environments

A full range of automotive electronic storage products

When the car is running, voltage stability and durability, sudden power outages, and limited storage space all raise problems that must be addressed with regard to in-vehicle memory.

Extensive technical customization and efficient service

Innovation laboratory opened to promote automobile storage business

In order to support the development of the automotive electronics business, Longsys has set up an innovation laboratory in Zhongshan Storage Industrial Park for the design and verification of regulation vehicles that can always remain open to customers. This lab is composed of six modules: design simulation, signal analysis, system verification, reliability test, material analysis, and failure analysis. In addition to meeting its own product design and verification demands, it also provides customers with signal simulation, SI analysis, board-level verification, temperature cycle verification, and failure analysis services based on customer systems. It provides a one-stop service for car manufacturers, covering everything from product design and verification to delivery and after-sales. Longsys understands that in such a complex in-vehicle environment, innovation is a must. It has therefore opened a joint laboratory along with intelligent vehicle manufacturers, thereby establishing a solid trust as well as storage application joint development. The company now has more than 1,000 employees, nearly 50% of whom are technical R&D personnel. It has set up a storage innovation base in the Shanghai Lin-Gang Special Area, which facilitates the provision of technical support and services to automobile manufacturer clients in South China and East China.

Rigorous reliability testing required for AEC-Q100

AEC-Q100 is an in-vehicle reliability testing standard developed by the Automotive Electronics Council (AEC). This standard is composed of seven major test items which are further broken down into 41 sub-items. The FORESEE automotive eMMC passed this verification in 2020. Any electronic parts that meet this standard are of high quality. This standard is also a specification to verify packaged integrated circuits.

In regards to memory chip testing, Longsys has independently designed more than 30 core testing algorithms and testing software, including testing scanning algorithms and multi-platform testing software. In terms of testing hardware, the company has independently designed and customized an automatic test bench with high frequency, low power consumption, and strong computing power performance based on a 10nm customized ASIC. In addition, with its proficiency in independent innovation, the company has developed a test socket that can perform direct high-temperature testing by enabling a rise in linear temperature from 0°C to 125°C. This avoids the hassle of having to remove the chip from the bench and send it to the high-temperature box for testing, as is required in conventional high-temperature testing. This innovation resolves the issue of inaccurate results garnered from conventional testing as a result of heating in the motherboard, which also accelerates the aging of the board. This innovation can also greatly improve testing efficiency. As of now, this is already being used in the testing benches for DDR (a memory bar), LPDDR, ePOP, and other products. In addition, through the innovative platform designed for cloud testing, Longsys has realized a process where both eMMC and LPDDR chips packaged in SiP package products such as ePOP/eMCP can be tested simultaneously in the same testing board.

Automotive storage built via quality management

With its business, Longsys has always been firm on what it considers the bottom line: branding, quality, compliance, and value. The company has built a comprehensive quality management system, which consists of five parts: resources management process, project quality management, production quality management, supplier quality management, and customer quality management. The company's supply chain delivery center has specially deployed a professional production supply chain that meets the requirements of automotive regulation and can sufficiently support both current and future business development. The management of each phase from customer demand, product development, and material selection, all the way through to production & delivery reinforces the inventory and the backup, and guarantees that the demand from automobile clients remains stable and perpetual.

Extensive customization with innovative technology

As with FAB's mature IP mode, Longsys' customization of storage technology has established modules of memory chip architecture, firmware development, hardware design, packaging technology, and system testing. This allows for clients' ideas to be brought to fruition expediently and for them to be applied on storage products without delay. The company's automotive storage products have a number of technical customization cases such as streaming media rear-view mirrors, regulation vehicle memory that is water-proof, dust-proof and shock-proof, in-vehicle personal data backup disks, and other innovative applications. Therefore, it is possible to provide services featuring differentiated customization for different automotive customers. A diversity of customization options is available for automotive storage products, including but not limited to: customization of chip appearance, software partition, pSLC function, and encryption function. These tailored services provide clients with several advantages including easy application, short cycles, and controllable costs.

Conclusion

As smart cars continue to develop rapidly, data edge computing, high-speed read/write performance, data security, and Internet trends for data will pose challenges for storage device manufacturers in terms of technology, quality, innovation, and service. Longsys has taken the lead in joining the Automotive Edge Computing Consortium (AECC), bringing it one step closer to the vehicle storage market. Longsys is determined to invest in deepening storage technology, elevating product quality, and broadening application innovation. In doing so, it will sufficiently reveal itself as a role model that can represent marketed and international Chinese enterprises.

we give our all

Phone:+86-13510641627

WeChat:Longsys_electronics

E-mail:marcom@longsys.com