News

Longsys SDP, Revolution of SSD Industry

2017.05.25

On August 25, 2016, Shenzhen Longsys Electronics Co., Ltd., the leading enterprise in China’s internal memory industry, preemptively unveiled SSD integral module product-SDP™ and it would bring about revolutionary changes to retail channel market and business mode of consumption-type SSD.

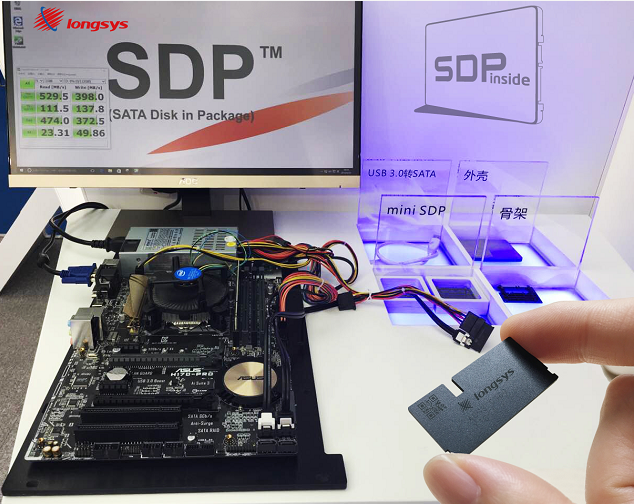

Longsys exhibited sample products of SDP™ mass production

Longsys SDP™ products VS standard SD card

SDP™ refers to SATA Disk in Package, the process that SSD main control chips and Flash chips are packaged to be integral modules and then sent to delivery after being card-activation mass production and testing. The form of this product equals to SSD semi-finished product. It becomes a completed SSD once the outer casing is supplementarily assembled. The small dimension, low power consumption, and lightweight of SDP™ are the highlights of this type of product. The dimension of the product is merely 33.4*17.2*1.23mm, the power consumption is as low as 1,430 MW. and its weight is approximately 1.9g.

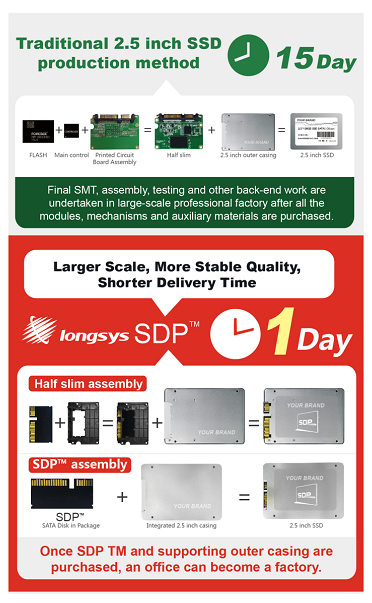

Quick-speed assembly can be realized in the office because of the simple assembly method of SDP™

The SSD market is generally divided into two categories: The first category is the server market and larger-scale OEM PC manufacturers. The current market is mainly dominated by large manufacturers with the utilization of the PCBA production method. The forms of the Datacenter SSD market and PC OEM SSD market are mainly M.2 PCBA and U.2 SFF-8639 forms, which are not suitable to be manufactured with the SDP™ method. The DIY retail channel market of PC is mainly 2.5 inch SATA SSD, the clients need quick-speed mass production and diversified customization and Longsys can meet client’s demands in the market of this category with its SDP™ products. It can facilitate the clients of the SSD brand and the clients aspiring to take up SSD business to quickly realize the intended products. The current main-stream method in the market is to get the Turn Key Plan of the main-control manufacturer first and then undertake PCBA assembly. The above-mentioned mode is more simple and faster when compared with this method.

What’s the advantage of SDP™ compared with the traditional PCBA mode?

Longsys SDP™ VS Traditional PCBA

Longsys SDP™ VS Traditional PCBA

Since the modularized manufacturing method is utilized, when compared with the traditional PCBA manufacturing method, SDP™ products can shorten the production time of SSD finished product from the existing 15 days to only 1 day. The production capacity increases from 15K/Day to 100K/Day. Additionally, the new SSD has more stable quality, shorter delivery time, and other advantages.

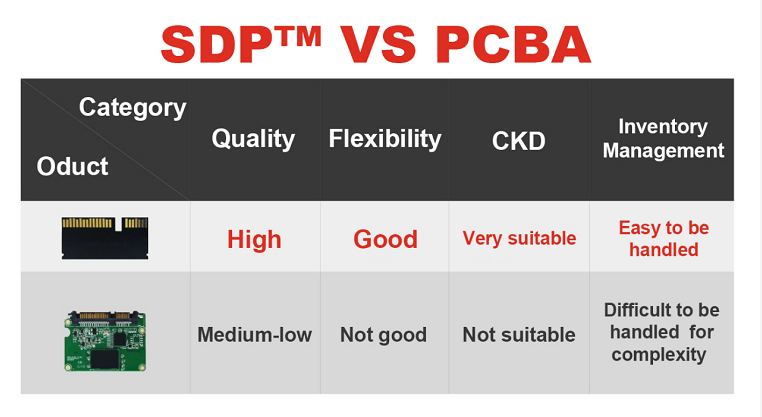

First, we’d like to say something about quality. Why the quality of products in Package Factory is better than that of products of SMT Chip-mounting Factory? If the PCBA with surface-mounted chip doesn’t conform to the requirements of the quality, soldering iron can be used to undertake second processing and repair. The component which has been already packaged couldn't be repaired. If the direct-pass yield rate is not controlled in a proper way, the costs will be extremely high. Thus, the supervision and control of the whole production process which includes the manufacturing method of SDP™ products are complex and strict. The packaging factory is required to obtain the grade according to the chip package test so as to guarantee the high quality and high yield rate of SDP™ products. "It can be compared to be an aircraft factory (Package Factory of SDP™ products), another one is the automobile factory (PCBA SMT Factory).” SSD Product Director of Longsys Zhong Mengchen said in a statement that, a disastrous accident would occur if there is any problem in package production of SDP™ products. Thus, the quality supervision and control of SDP™ Package Factory is required to be very strict and precise.

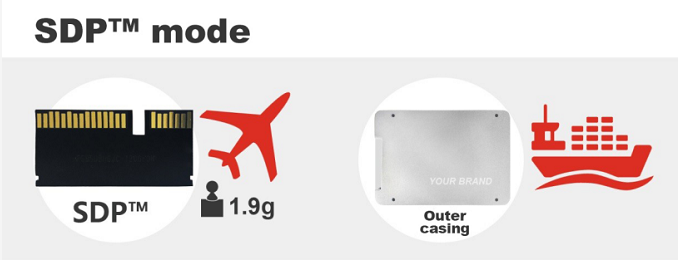

SDP™ Transportation Mode of Longsys

In addition to quality assurance, the SDP™ product also has advantages in the aspect of logistics. "For example, if 2.5 inch SSD is required to be delivered to the US since the price of Flash product is inconsistent fluctuation, the clients wouldn’t dare to stock too many goods if the traditional PCBA method is utilized. If maritime transportation is chosen, we couldn’t manage to quickly cope with the market fluctuations since a long time would be taken. However, the costs will also be high if air transportation is chosen for products.” Zhong Mengchen stated that the current SDP™ mode is that the outer casing of SSD is transported by ocean shipment (it lies in that the outer casing has a large volume and heavyweight, however, the price is stable.) While SDP™ can select air transportation for its small volume. Thus, the client’s goods pick-up quantity can be avoided to be affected by the quick fluctuation of Flash price to the maximum limit. The operation is consequently more flexible.

Aiming at the Export market, SDP™ resolved the core complex CKD problem

SDP™ products can completely meet markets that have high tariffs. Since SDP™ products belong to semi-finished products, the tariff costs can be reduced if it is transported as CKD. It is learned that currently many countries have increased tariffs on the complete machines of electronic products, some of these countries even require that a certain ratio of components shall be purchased at the local places. CKD is applicable to the countries which have high tariffs or have demands on local production, including India, Southeast Asia, and South America, etc.

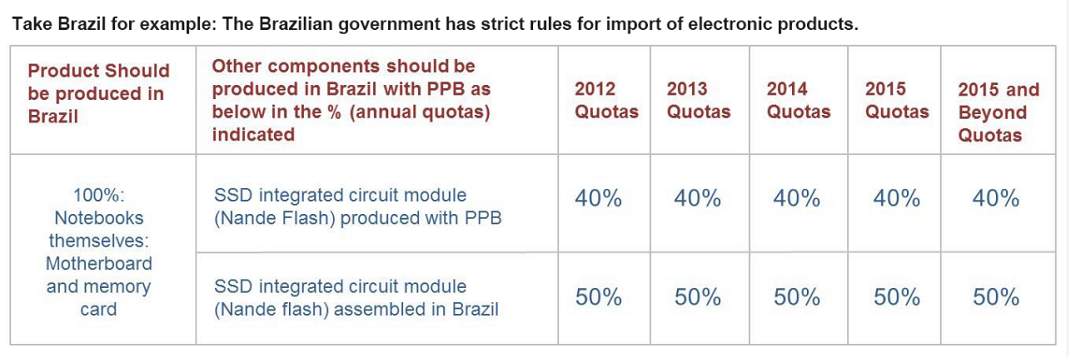

Zhong Mengchen mentioned that the laptop market in Brazil could be taken as an example here. Brazilian Government requires that 40% memory components shall be purchased at a local place. These components include memory chip DIMM and SSD (Solid State Disk). The local purchase partially requires that the manufacturing process starting from Flash to package shall be undertaken in local Brazil. In addition, the remaining 50% are permitted to deliver spare parts by the means of CKD. Then the assembly or SMT can be realized at a local place.

The Brazilian Government has strict regulations on the import of electronic products.

"SSD couldn’t be popularized in the Brazilian market in the past, due to its expensive price as well as the troublesome manufacturing process. In addition, the drastic fluctuation of the exchange rate in Brazil also increases the difficulties for business negotiation.” Zhong Mengchen stated that being compared with SSD, the advantages of SDP™ products became more remarkable in the Brazilian market, all the work including package, testing, card-activation mass production have been completed. The product could be considered as a semi-finished product. However, in terms of local policies, this SDP™ product remained to be parts and components. "Thus, SDP™ product not only reduced the costs of customs duties, more importantly, but it also resolved the complicated CKD problem and the after-sales service would become simpler.” Zhong Mengchen stated that, in addition to in South America, it would be also applicable to the Russian market.

Mature supply chain contributes to the establishment of SDP™

As early as eight years ago, Longsys initialized UDP module (USB Disk in Package) in the industry of USB flash disk, this kind of module changed the traditional SMT production of USB flash disk, currently, it has become the benchmark in the market of USB flash disk. However, the transplantation of this mode to the SSD industry also encountered hindered advances. SDP™ products have more design and technical difficulties than UDP. According to Zhong Mengchen, Longsys started to plan the SDP™ project in 2014, however, it came across many technical challenges at that time. It lies in that the integral package needs a 28 nm SSD controller equipped with ultra-low power consumption. While the main control chips at that time main control chips couldn’t meet the demand. Since the development of main control chips currently has come to this time node, which facilitated the conditions for mass production of SDP™ products to become mature. After one year’s firmware development, SDP patent portfolio application, and integral outer casing design, then after half a year’s optimization and mass-production preparation, Longsys finally has the chance to realize mass production in the first quarter of the current year.

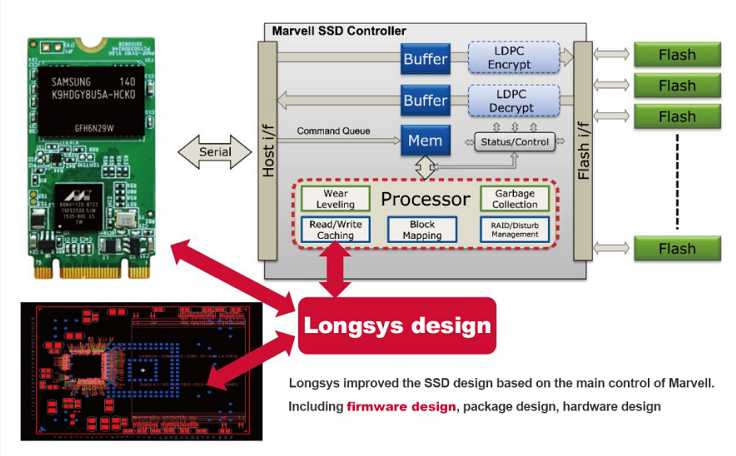

Longsys and Marvell reached a strategic cooperation and completed the design of SSD products based on the main control of Marvell.

"This module has a small volume but high capacity. In addition to the main control and Flash, there also exist many components. For example, there are eight Flash chips and one main-control chip in 128GB SDP™ products as well as a source of power, crystal, reset chips, etc. The comprehensive surface-mount package actually is complicated.” SSD Product Director of Longsys Zhong Mengchen introduced the technical difficulties of Longsys SDP™ products, he indicated that the higher the SSD read-write speed, the higher the power consumption. When compared with the products of competitors, the power consumption of Longsys’s SDP™ products is merely 50% of that of competitor’s products. In the meanwhile, the heat dissipation effect is very good. Along with main control chips, the mass production of SDP™ products also takes benefits from the increased density of flash memory chips. "In the past, the internal memory of a chip is merely 2GB or 4GB. While the chips currently can have an internal memory of 16GB or 32GB. The internal memory of a chip will attain 64 GB for the next year. For the moment, we merely need four pieces of Flash disks for the intended 256GB and we merely need eight pieces of Flash disks for the intended 512 GB.” SSD industry is currently transformed from 2D Flash to 3D Flash, the further improvement of SSD storage precision means that SDP™ products could realize larger memory capacity, higher yield rate for the same memory capacity as well as lower cost.

Being equipped with Intellectual property right protection, SDP™ is not afraid of any challenge.

Previous New Smart Storage for IoT Longsys products Show (Taipei) 2017.05.26

Next Longsys First iOS Memory Cable 2017.04.16

we give our all

Phone:+86-13510641627

WeChat:Longsys_electronics

E-mail:marcom@longsys.com