News

How Longsys builds a win-win SSD ecology?

2016.08.25

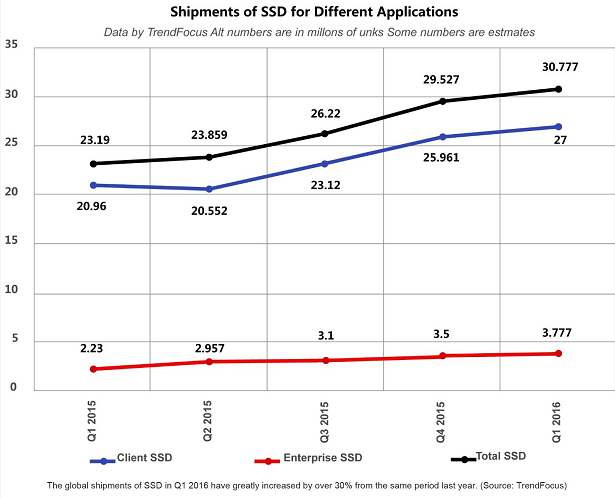

Research data of TrendFocus shows that global shipment of SSD in the first quarter of 2016 exceeds 30 million, with year-on-year growth of 30%; and it is estimated that global shipment of

SSD will be swiftly increased to about 0.24 billion in 2020 from 0.1 billion in 2015.

Rat race: analysis of weak points of SSD retail market

Fierce competition hides behind the sharp increase in SSD shipment. SSD market is gradually being polarized: Flash original manufacturers mainly focus on the data center with a high-profit rate, while it is hard for non-Flash original manufacturers to permeate into the SSD market of a data center due to steady supply and compensation capacity.

As for the retailing and DIY personalized market, as well as scattered demands of industry customization and intelligent hardware, there are not many Flash original manufacturers who are willing to provide service due to market segmentation and small single order.

Domestic medium & low-end brands and white brands are mainly oriented to the universal SSD market. Now the market mainly takes the place of traditional hard disk application, which is featured with the low-end product and much sensitive price. Since the profit rate of universal SSD is too low, and the selling profit of Flash is higher than that of SSD, which further promotes the support of Flash original manufacturers for domestic SSD manufacturers. President Cai Huabo of Longsys thinks that with the clarification of market size, the resources of the domestic SSD industry have been increasingly concentrated, while many low-quality and small-scale SSD suppliers will be eliminated naturally.

In terms of SSD channel marketing, the present online retail market remains dominated by a small minority of brand manufacturers. As for offline channels, because low prices of new brands will bring a market share, leaving slim profits to channel distributors, channel marketing drive is not so positive. To middle and low brands, consumers lack a degree of loyalty but attach importance to product parameters and prices. Survival is hard when 2nd-tier and 3rd-tier individual brands alone are involved in limited marketing efforts.

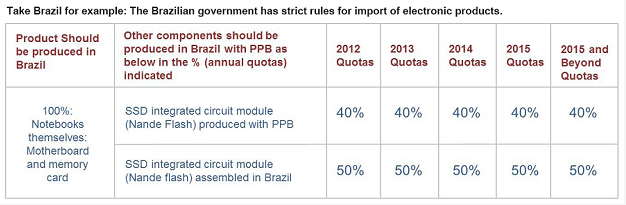

As for export-bound brands, higher and higher duties levied upon integrated electronics and harsh law terms have also become a headache. Up to date, many countries improve their duties upon electronic products and even request purchasing of a portion of local components. CKD applies to those countries with high duties or those having local manufacturing needs, such as India and other countries in Southeast Asia and South America.

Take Brazil for example The Brazilian government has strict rules for the import of electronic products.

"To make CKD, we must contract out resistance, capacitor, master control, flash memory, adapter, and PCB parts; we also have to teach local sticking manufacturers how to carry out SMT (surface mount technology) procedure and how to do mass production test. This is great trouble. It takes 30-40 hours from Hong Kong to the destination by air. Once some problem pops up, it is difficult to go there for support. ” said Cai Huabo.

Longsys firstly launched SDP™ to improve SSD industry efficiency

In response to a similar market scenario, MTK launched a Turnkey (one-stop solution) Mode, in which baseband chip, operating software, and even LCD, camera, and other parts are integrated as a "one-stop assistance solution”, thereby greatly reducing the manufacturing duration of cellular phone and of course, the R&D costs.

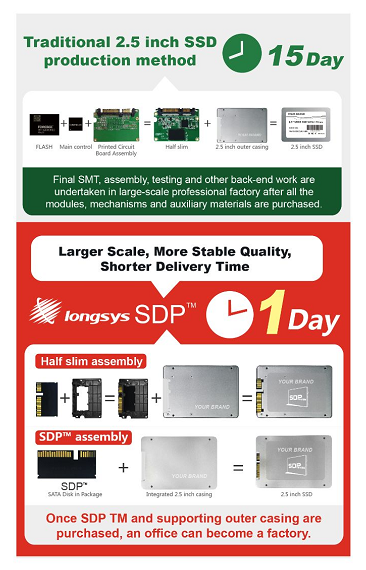

Longsys innovatively launched the integrated SDP™ (SATA Disk in Package), which represents what it learned from MTK’s experience. In the packaging house, Longsys packaged the SSD master control chip and flash it into the integrated module product (SDP™), which will then experience SMT procedure and testing before it is delivered. Compared with conventional PCBA mode, SDP™ products have comprehensive advantages, whether in quality, capacity, delivery speed, cost, and flexibility, or in CKD, warehouse management, and after service.

"The integrated SDP™ is produced with the advanced packaging technique and strict self quality control. To the industry chain, manufacturing processes are centralized in the packaging house, and marketing efforts are decentralized to individual salesmen. Compared with the previous PCBA mode of SSD production, SDP™ mode gives more scientific control, ensuring better product yield and consistency. To put it alternatively, the use of a chip module making method for SSD production will greatly shorten the intermediate processes, making it more convenient for downstream clients and channels to prepare goods and turn overstocks. Moreover, product inspection, test, and after-sales disposal will become much simpler accordingly. Apart from lowering the costs, the improved efficiency will better help clients to improve efficiency.” said Cai Huabo.

"SDP™ product series we make are the result of us thinking about how to change our SSD manufacturing mode and marketing pattern. Longsys has no SMT factory of its own, so SSD is accomplished via outsourcing. Neither does it has its SSD brand facing consumers. When the manufacturing costs are not advantageous and the sale price not sufficiently at a premium, our conventional mode of SSD marketing is not competitive.” said Cai Huabo, "As early as 8 years ago, UDP (USB Disk in Package), which was innovated by Longsys using packaging method, changed the conventional way of USD disk production with SMT, and until today, it has long been the standard in the USB disk market.”

"Based on the experience of UDP successes, Longsys put forward the integrated SSD program, but SDP™’s designing and technical difficulties are much greater than UDP’s. ” explained Cai Huabo, "In 2014, we already started the planning of SDP™ program, when we ran into lots of technical challenges. Because the integrated packing needed SSD controller with low power consumption, we patiently persuaded Marvell into providing control and opening native code. Following one year’s firmware development, patent portfolio/application and integrated casing design, and then half a year’s optimization and pilot production, we can achieve scale production by the end of this year. ”

First to launch "SDPinside™”; devoted to a win-win SSD ecology

Longsys has submitted SDPinside trademark registration to main countries over the world.

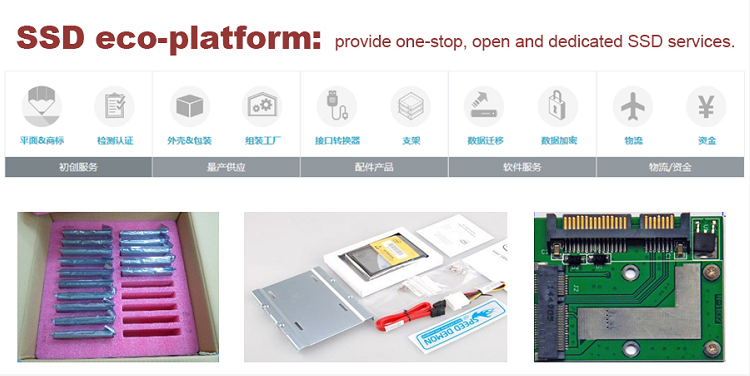

As long as SSD brand service providers and distributors use Longsys’ SDP™ products, they can join in the "SDPinside™” turnkey program. This program will provide multiple services such as customized production, financial guarantee, credit endorsement, service platform, and online customer service. "The symbiotic relationship is the natural law for the development of SSD eco-chain. Longsys led the efforts to initiate and promote SSD eco-chain sharing in the SDD industry; it also drives more SSD-related enterprises to spontaneously invest resources in jointly building the SSD eco-chain,” said Cai Huabo.

Longsys is vigorously building the SSD eco-platform to allow for the involvement of more SSD supply chains.

"Longsys is something like Israeli status in the memory device industry, for only innovated products and business modes can help a company to earn its competitiveness and market status. Longsys is making memory products and customer services which OEM manufacturers dislike, fail to foresee and cannot make, in order to gradually expand its survival spaces. ” said Longsys president Cai Huabo, "Longsys intends to use its own development capacity and flexible customer strategy to act as a compliment and an aide to OEM manufacturers in a differential manner, thereby serving various clients well and meeting market demand.

The future aim of Longsys is said to promote "SDPinside™” among consumers and to regard it as Longsys’ quality commitment to SSD customers. "Be reassured that our customers will confidently use our products. We ensure quality and supply, and try to build a sound ecological code of SSD. ” said Cai Huabo.

In addition to conventional sectors like data center and PC, Longsys is very optimistic about SSD applications in monitor device market and person data storage, especially low-power consumption, small-sized application, and those in relatively extreme environments such as high/low temperatures, dampness, and vibration, as well as monitor device application (e.g., real-time data transmission). In these fields, SSD will rapidly replace conventional hard disks. Nowadays cloud storage is unsafe and must be paid for. Additionally, SSD, which is characterized by a bigger capacity than a USB disk, high quality, fast transmission, stable performance, fingerprint encryption, and other advantages, has become the demand growth point in the personal data storage market. Longsys has pioneered its developmental force in the said two markets.

Previous Longsys 3D NAND TLC SSD Leads New Trend 2016.09.06

Next Longsys Continues Cultivating Mobile Storage Devices End-market 2016.07.01

we give our all

Phone:+86-13510641627

WeChat:Longsys_electronics

E-mail:marcom@longsys.com